We occasionally link to goods offered by vendors to help the reader find relevant products. Some of these may be affiliate based, meaning we earn small commissions (at no additional cost to you) if items are purchased. Here is more about what we do.

We’ve covered the components of many Western-style knives in previous guides, like the chef’s knife and bread knives, and now it’s time to explore some of their counterparts among the increasingly popular Japanese styles.

In todays hot cutlery market, the primary differences between Western and Japanese blades pertain to the materials used in construction, and specialized designs for specific purposes.

But there are other considerations as well. Handle shape, single or double beveled edges, and finishing details are also important.

So let’s have a closer look at these beautiful tools to see exactly what the differences are, and whether they’ll be a good fit for your culinary practices and skills. Once you understand their different natures, you can be assured that you’re prepped with the knowledge to find the best one for you.

Table of Contents

Types of Japanese Kitchen Knives

European chef’s knives are multipurpose masterpieces, and culinary workhorses. They’re used for everything from the tough work of hacking up a chicken to more delicate tasks such as mincing herbs, and everything in between. It’s the Clydesdale of kitchen blades, plowing through all sorts of tasks.

On the other hand, Japanese chef’s knives are more delicate, somewhat counterintuitively due to the hardness of the steel, and they have more specialized applications. As such, there are four different styles that could be considered chef’s knives – some of a general purpose nature, with others excelling at distinct tasks.

These Eastern blades are more like a fine Arabian. They dance and prance and require some patience to use, but when you get to know them, they perform exquisitely.

The Gyuto/Gyutou/Chef’s

In general, the gyuto has several characteristics in common with a Western-style chef’s knife.

Somewhat of a hybrid between a traditional Japanese nakiri and a Western cook’s knife, it has evolved to handle multiple duties – slicing veggies as well as fish and meat. As such, it has a longer, thin blade and is quite nimble.

The profile of the blade is quite similar to those of a French sabatier, although the belly curve of the cutting edge is less pronounced. Depending on the blade profile, you can rock chop with some gyutos but most are really designed for push chopping.

The Misono UX10 Gyuto is a favorite among professional chefs and is a great choice for the home as well. Available on Amazon.

The truer edge profile gives it more contact with a cutting board, providing a larger cutting surface than European versions. And it doesn’t need to be lifted as high, which results in less fatigue and more efficient cutting.

Also, the tip will often be a bit lower, more in line with the center of gravity, as opposed to sitting high and closer to the spine. This makes it very good for finer detailed work, as well as decorative presentations.

With a double beveled edge, it’s sharp on both sides and usually measures between 8 and 12 inches. Gyutos, and the others listed below, are available with either a Western style, ergonomically-shaped handle or in the traditional “wa” form – straight, with a round or octagonal profile and usually constructed of hardwood.

This Yoshirhiro Stainless Steel Gyuto is an excellent choice for those wanting a “Wa” style handle. Available on Amazon.

The gyuto is a lightweight, all-purpose knife that excels at precision work like mincing, and fine preparation of both vegetables and light proteins. However, this type won’t perform well when cutting through dense materials such as bone or cartilage, or slicing through large items like Hubbard squash.

Return to the Table of Contents

The Santoku (Home Chef)

The Santoku is another general purpose kitchen knife with a similar appearance to a cook’s knife, but it is shorter, thinner, and more agile, combining the features of a gyuto and a nakiri.

Measuring between 5 and 7 inches, it features a flatter edge and a sheepfoot tip, with a dramatic angled point of up to 60 degrees.

Misono UX10 Santoku, available on Amazon

With a slight angle on the cutting edge, it does allow for some rock-chopping, but there is very little tip travel due to the sheepfoot profile – push cutting in a straight up and down fashion is easier and more efficient.

A typical santoku will have a Western-style, double beveled edge, and maintains a uniform thickness from spine to just behind the cutting edge. The blade may be flat or incorporate granton divots for better food release.

The tip shape, plus the height of the blade, makes a santoku great for scooping food, and it provides a solid and safe fulcrum point for the off hand when mincing.

Like a chef’s knife, the santoku can be used for a variety of cutting jobs in the kitchen. Lightweight, nimble, and easy to maneuver, they’re great for chopping and cutting tasks, but lack the blade length for jobs like slicing up fish or meat.

Return to the Table of Contents

The Sujihiki (Slicer)

The sujihiki has a long, narrow blade with a short height that’s designed for slicing boneless meat, fish, poultry, and game.

The short height means less surface area, which reduces friction – making it ideal for cutting ultra-thin slices of your favorite protein. Even oily or fatty fish won’t stick to the small surface.

Once again, the Misono UX10 line takes the top spot with its Sujihiki offering. Available on Amazon.

A long, thin blade, usually in the range of 9.5 to 12 inches, glides through large pieces of protein without the need of a sawing motion.

The cutting action is a single draw or pull that provides a clean, precise cut without any ragged edges or torn pieces, and requires a light, deft slicing technique.

Often considered to be the Western version of the traditional sushi/sashimi knife (the yanagi), the sujihiki is similar in size and function to that of a conventional carving knife – which makes it ideal for slicing and portioning.

The Torijo DP line is well know for providing the best bang for the buck and offers incredible value for the price. Available on Amazon.

The suji is usually a bit lighter and somewhat more flexible than a yanagi, which makes it useful for trimming as well as slicing duties.

Another notable difference between the sujihiki and the yanagi is the edge shape. A yanagi will be single beveled, while the suji has a double bevel.

Some manufacturers produce sujihikis with fluting, granton divots, or a hammered profile above the cutting edge to further reduce friction and prevent sticking. However, this is often more aesthetic in nature, as the overall design is usually effective enough to slice cleanly without the added dimples.

Read our comprehensive sujihiki slicing knife buying guide now!

Return to the Table of Contents

The Nakiri (Traditional)

The nakiri is a traditional vegetable knife designed for full, rhythmic chopping strokes.

With a shape similar to a short cleaver, it has a flat profile characterized by a thin, straight blade – although some may have a slight curve toward the blunt edge. A substantial spine tapers to a square, blunt tip, but it is thin behind the edge with a symmetrical, convex grind.

Made with superior VG-Max stainless steel, the Shun Nakiri is a customer favorite. Available on Amazon.

Created for the primary purpose of slicing, dicing, and chopping veggies, the blade length is usually between 5 and 7 inches, which is ample length for most vegetables.

With a double bevel edge, food falls off easily as the blade glides through what you’re prepping, and the square tip makes it one of the safest to use in the kitchen (and you can’t be too careful about kitchen safety!)

Because of the flat edge, a rocking motion is pretty much impossible – instead, the nakiri utilizes a straight up and down motion, without the need for any horizontal pushing or pulling. You can make paper thin slices and ribbon cuts as the edge travels through the food to the cutting surface with clean, even cuts.

Due to the thin, refined cutting edge, they’re excellent for using on delicate veggies and herbs without bruising or crushing delicate tissue. Plus, the rectangular shape and height makes them ideal for scooping large amounts of food.

Very similar to a usuba, the nakiri is most often used by home cooks while the usuba is preferred by the professional chef.

Return to the Table of Contents

Petties and Utilities

A petty knife has the same basic application as a Western paring or utility knife, with a longer blade.

Blade lengths for petties vary considerably, running from 3.5 to 8 inches, with a height of 1 to 1.5 inches from heel to spine. The blade profile is generally triangular in shape, lifting from the heel to tip, and the edge is ground in a double bevel.

The Tojiro DP Petty is by far the best bang for the buck in this category. Available on Amazon.

Like the utility knife, a petty is nimble and handy for small tasks that require some agility.

The main difference between Eastern and Western styles is that the petty knife can be used for mini chopping duties on a cutting board, while a paring knife is better suited to handheld tasks.

See our Petty and Kitchen Utility Knife Guide now!

Return to the Table of Contents

Paring

Again, these are similar to their Western counterparts and often feature Western-style handles.

These are short little blades designed to be used in hand for delicate work, such as peeling fruits and veggies.

The paring knife is usually under 3.5 inches.

Tojiro DP 3.5-inch Paring Knife, available on Amazon

In this category, we are fond of the inexpensive Torijo brand, as shown above.

Return to the Table of Contents

The Bread Knife

Although not a traditional Japanese shape, some of the best bread knives in the world are designed and made there.

Not only for bread, these surprisingly versatile tools are excellent for slicing tomatoes, sponge cakes, and other squishy foods.

We’re in love with the MAC version and found it to be the best in our recent testing for Foodal’s bread knife round up, which you can check out here.

Mac Knife Superior Bread Knife, available on Amazon

In fact, three of our top rated bread blades are Japanese.

Return to the Table of Contents

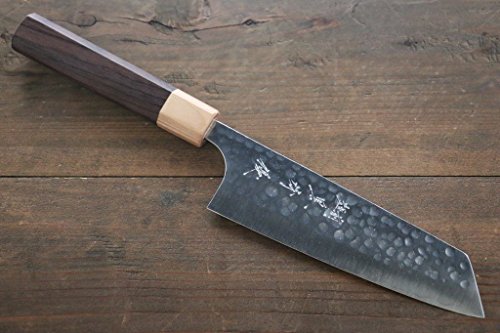

The Bunka

The bunka is a general purpose knife that can handle a wide range of kitchen duties. It’s particularly adept at making fine slices of smaller items such as herbs, garlic, celery, shallots, carrots, and the like.

The medium-sized blade generally measures around 5 to 8 inches in length with a tall profile, anywhere from 2 to 3 inches from heel to spine – which also makes it a handy utensil for scooping duties.

Yu Kurosaki R2/SG2 Steel Hammered Bunka, available on Amazon

The relatively flat cutting edge of the bunka has a double bevel, and it is ideal for push cutting and chopping. A very subtle curve does make a rock chop possible – but they’re not particularly efficient for this stroke.

Similar in many aspects to the santoku, the bunka is smaller and thinner, and has a noticeable convex cross section just above the cutting edge that provides a good release on vegetables as well as proteins.

The sheepfoot tip gives good control when working with meat or fish, and gives it the dexterity for more delicate work like trimming and paring.

And thanks to the height of the blade, a bunka will usually provide good knuckle clearance when chopping or push cutting, when used with a modified pinch grip.

The bunka is NOT very common, even in Japan, and is normally made in small batches using exotic steel by independent smiths and small craft shops. These tend to be very pricey.

Return to the Table of Contents

The Chukabocho (Cleaver)

The Japanese version of a Chinese cleaver is called a chukabocho. A multipurpose cutter, every part of the blade can be used for preparation of fruit, vegetables, herbs, and spices.

But these large cleavers are not intended for prepping or dressing bone-in meats – you’ll want a true meat cleaver for that purpose.

Large and rectangular in shape, the blade length is around 7 to 8 inches with a height of 4 to 5 inches.

The Shun DM0712 Classic Vegetable Cleaver recently came in at the top in our recent cleaver shootout. Available at Amazon.

The end is blunt and square with a thick spine that tapers down to a thin, scalpel-sharp cutting edge that features a double bevel for versatile performance. The cutting edge is usually die-straight, but can have a slight curve up to the tip.

Surprisingly nimble, pretty much every kind of chopping and slicing technique works with a chukabocho – as long as the edge has a curve for rock chopping.

Effective at reducing large veggies like a cabbage, the thinness of the blade also makes it adept at delicate tasks like mincing herbs, and trimming and peeling as well.

This Yaxell Ran 7-inch Cleaver is one of the best of its kind. Damascus cladding over VG-10 stainless steel along with a black micarta handle sets it apart from the competition. Available on Amazon.

Use the flat of the blade to smash items like ginger, garlic, or shelled nuts, or the spine to tenderize boneless meat. And of course, the large area of the blade makes this the best tool for scooping and moving mountains of food. Read more about vegetable cleavers now.

Return to the Table of Contents

The Western Deba (Western Chef’s)

The Western deba is another general purpose knife that’s very similar to a chef’s knife, but designed for more heavy duty performance than a gyuto.

Blending the functions of a chef’s knife and a cleaver, the relatively thick blade generally measures between 6.5 and 10 inches, with a height around 2 inches – although larger ones are available.

And they have some belly to the cutting edge, which makes them suitable for rock-chopping. Point styles vary as well, with some having a dropped tip, while others stay elevated closer to the spine.

Masahiro is another well-known and respected Japanese knife maker. Their inox (stainless) Western-style deba is a great choice for any home or professional kitchen. Available on Amazon.

Not to be confused with a traditional deba, which has a single bevel edge and is specialized for cutting fish, the Western deba has a double bevel edge. Other features of note include a thick spine and heavier weight, and it’s often used for tough duties like cutting through joints of chicken or beef, as well as fish bones.

The edge is usually ground to a more obtuse angle than traditional Japanese blades, and coupled with the bilateral edge, provides enhanced durability as well as versatility. And most often, a Western deba will have a Western-style handle.

Big and sharp with a solid heft, a Western deba can easily handle splitting seafood like crab, shrimp, and lobster, and will effortlessly tackle large fruit and veggies such as gourds, squash, or pineapples.

Although they’re more rugged than the others mentioned here, they’re still crafted of hard carbon steel, and shouldn’t be used on frozen foods or for butchering very hard and thick bones.

Return to the Table of Contents

The Deba

Like the Western deba, a traditional deba is also thick and stout, but it has the primary application of butchering and filleting fish.

The blade length of a deba usually measures from 6.5 to 8 inches, although there are some as small as 4 inches in length.

Yoshihio Shiroko High Carbon Steel Kasumi Deba, available on Amazon

Blade height is around 1.5 to 2 inches, and the edge is ground to an acute angle in a single bevel, with a flat backside.

Excellent for cutting the soft flesh of fish as well as fish bones, some chefs use them to break down poultry and for cutting vegetables as well. But the single bevel can make this onerous for those unfamiliar with the proper technique.

Completely different from a flexible Western fillet knife, the deba is robust and heavy. A different skill set is required to use this type without squishing the flesh.

Return to the Table of Contents

The Funayuki

The funayuki was originally used on fishing boats, primarily as a lightweight filet knife to test quality of the catch, for cleaning and fileting fish, and for doing meal prep.

Smaller and shorter than a yanagiba (the blade of choice to prepare sashimi and other types of sushi, and for slicing raw fish and seafood), it has a delicate, thin blade that requires a skilled hand to use it without chipping the edge.

Yoshihiro High Carbon White Steel Kasumi Funayuki, available on Amazon

The blade measurements range from 5.5 to 8.5 inches, and it can be as tall as 2 inches from heel to spine.

The cutting edge can be either single or double beveled, quite flat with a minimal belly, and a very thin cross section – which makes it good for delicate, precise tasks.

A jack of all trades, smaller funayukis are often used like paring knives for peeling and trimming, as well as for the preparation and fileting of fish.

A handy knife for multiple duties, it can be a bit of a princess due to the ultra-thin, fragile blade.

Return to the Table of Contents

The Hankotsu

The hankotsu is a tough little knife that’s used for light butchery. It is ideal for tasks such as boning, trimming meat, getting in between bones, breaking down poultry, and Frenching a rack.

These feature a sharp, pointed tip that can be inserted into a cut and run along a bone, connective tissue, or fat. The hankotsu also has a short height, around 1 to 1.5 inches, that makes the blade nimble enough to be turned and maneuvered easily while cutting.

A unique feature of the hankotsu is the cutting edge close to the heel area – these actually don’t have a heel.

Misono Molybdenum Hankotsu, available on Amazon

Depending on the make, anywhere from a quarter to a third of the edge length at the heel end remains unsharpened. This provides a strong edge for any scraping that needs to be done, and offers a bit of finger protection against slipping.

Keep in mind that without a heel, there’s no finger guard either.

The blade length usually measures around 6 inches, and the edge is technically double beveled – but it is ground at an asymmetrical angle, in a ratio of about 90/10 to the right side.

If you’re left-handed, this may not be the best choice. It’s going to be awkward for vertical boning, unless you special order one for left-handed use.

Hankotsus also require special care when sharpening and honing. All of the sharpening action takes place on the greater angle, or right edge, while the smaller angle is only touched to remove burrs.

The hankotsu has a thick spine and brawny cross section, and you’ll find these don’t have quite the same amount of flex as Western-style boning knives.

Heavy duty in construction, they usually have a beefy handle to provide a secure grip and maximum control.

Return to the Table of Contents

The Honesuki

The Honesuki is another boning knife, but this one is designed for the specific task of breaking down poultry and cutting through joints – but not for cleaving bones.

With a distinctive triangular profile that runs from heel to tip, the blade is quite stiff with little flex to it, and a perfectly straight cutting edge. Blade length runs from 5.5 to 8 inches, and it measures about 1.5 inches from heel to spine.

Shun Dual Core VG0018 4.5-Inch Honesu, available on Amazon

Like the hankotsu, traditional honesukis have an asymmetrical edge ground to the right side. But more recently, honesukis with an equal 50/50 bevel on both sides have become available, making these models a good option for left-handed users.

Due to the compact size of this knife, it’s also handy as a general purpose utility knife.

Return to the Table of Contents

The Kiritsuke

The kiritsuke is a hybrid knife designed to work as a fish slicer and a vegetable knife. Long and lean, it has a striking sword-like appearance with a sheepfoot tip, and is one of just a few multipurpose blades that are used in Japanese cuisine.

Traditional styles have a blade length of 10 to 12 inches with a single beveled edge, and are relatively short in height, about 1.5 to 2 inches. The profile features a straight edge, and some will have a hint of lift toward the tip.

Shun Dual Core VG0017 8-Inch Kiritsuke, available on Amazon

Westernized versions will often have a double bevel, with blades as short as 6 inches.

Kiritsukes are best used for slicing and push cuts. These perform well on vegetables, raw fish, and cooked proteins.

The tip is quite nimble for tap cutting, and the long blade is exquisite for thin-slicing veggies, or cutting them into a nice julienne or brunoise.

They’re also a good choice for cleaning and portioning fish, or thin slicing proteins for a graceful presentation.

Novices unfamiliar with the performance of a single bevel often find the traditional versions difficult to use, with wedging and twisting being common complaints. But the double beveled version gives it more versatility for those with less-than-masterful cutting skills.

Return to the Table of Contents

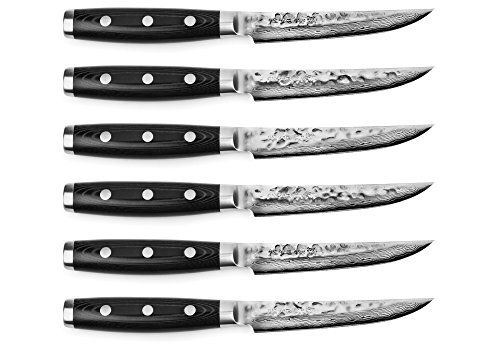

Steak Knives

Japanese steak knives are different than their Western counterparts, in that they have no serrations.

Constructed of steels that can be ground to razor sharpness, and with a tight 16° bevel, they will glide through a steak, leaving a clean edge that keeps flavorful juices inside, where they belong.

Enso HD 6-Piece Steak Knife Set, available on Amazon

The blade length is 5 to 6 inches, and the cutting edge profile rises from heel to tip, or may have a slight recurve to ensure smooth, one-stroke slicing. The length is ample to cut through even large steaks, but short enough to provide superb control.

And because they’re serration free, they can easily be sharpened at any time.

Return to the Table of Contents

The Yanagiba

The yanagiba is a sashimi knife, traditionally used to slice and portion boneless fish, seafood, sushi, and sashimi.

Long, thin, and slender, sashimi knives are graceful tools designed to cut in a single pulling stroke that creates clean, sharp edges using only the weight of the knife – and the longer the blade, the better the results.

Yoshihiro Stainless Hongasumi Yanagi with Rosewood Handle, available on Amazon

Blade lengths range from 8 to 12 inches, with a short height of about 1.5 inches. The edge is ground to a single bevel for superior sharpness, and to a sharp, pointed tip. A hollow grind on the backside helps to release pieces after slicing.

The bevel is typically ground on the right side, but left-handed versions are available through special order.

Traditionally used by sushi chefs, this elegant blade is gaining popularity with Western cooks for use as a carving knife.

Return to the Table of Contents

Features to Consider

Hardness

One of the most significant differences when comparing Japanese blades to their Western cousins is the high carbon content and high quality of the steel used, which results in a very hard steel.

Why is this significant? A harder steel can be sharpened to a more acute angle, which makes slicing more effective – typically about 15-20° for Japanese blades, and 20-30° for Western ones.

Hard steel will also hold a sharp edge longer, so these won’t require honing or sharpening as frequently. And, the cross-section of the blade can be made thinner, which reduces weight and improves agility.

The industry standard for measuring hardness is the Rockwell Scale. The higher the number, the harder the steel. An increase of one degree on the scale represents about a ten percent increase in hardness.

Typically, a chef’s knife of European origin will range between 52-56 HRC, or Rockwell Hardness based on the C scale. This number is determined based on scales ranging from A through G, with B and C being the most commonly used. This measurement can be as high as 58 for the Euro version, depending on the make and quality.

In comparison, Japanese blades rarely measure less than 60 HRC, often as high as 64 – a dramatic difference.

Types of Steel

Though it’s certainly an advantage, there are some downsides to metals measuring higher on the Rockwell scale. Extreme hardness is often paired with brittleness. This means the edges of Japanese blades have a tendency to chip or break when used against dense materials, like bone or tough gourds.

Tempering will reduce the hardness of steel and toughen it up against chipping, but this comes at the cost of the highly prized sharpness.

Stainless vs. Carbon Steel

To help counter the brittleness of hard steel while retaining the corrosion and stain-resistant qualities of stainless, manufacturers of Japanese knives have formulated many specialized, high-performance steel alloys.

These formulas will enhance specific characteristics in the end product, such as sharpness and durability.

Here are a few of the more common elemental additions to these high-quality steel alloys:

- Chromium (Cr) – is the main addition to stainless steel that improves stain resistance.

- Cobalt (Co) – will increase strength and hardness, and binds the characteristics of individual elements in complex steels. And, it also allows quenching at higher temperatures for a harder product, with a higher HRC rating.

- Copper (Cu) – will increase corrosion resistance, and is used as a brazing agent in composite blades.

- Molybdenum (Mo) – increases strength and hardness, as well as adding toughness due to its hardening properties. It also improves corrosion resistance and machinability.

- Nickel (Ni) – adds strength and toughness.

- Vanadium (Va) – increases strength and toughness as well as improving wear resistance, and makes sharpening easier.

- Tungsten (W) – adds strength and toughness, and also improves hardening properties.

When shopping stainless and stain resistant knives, look for names such a VG-10, VG-Max, Molybdenum, inox, and SG2. All of these represent a form of stainless.

And for the professionals and serious users whose primary concern is sharpness, Japanese knives are also constructed in the traditional way, with purer forms of carbon steel.

They provide outstanding hardness and performance, but they do come with the staining properties of carbon, with an even more brittle nature.

- White Steel – has the highest levels of purity, and is known for superb sharpness and ease of re-sharpening.

- Blue Steel – has similarly high levels of carbon as white steel, but will have additional elements such as tungsten and molybdenum for better edge retention and durability.

- Powdered Steel – comes with a rich chemical composition with the addition of chromium, vanadium, and molybdenum. It offers a very hard cutting edge, superior performance, and good rust resistance.

Most of our recommended models in this guide are stainless, with a few of the uncommon patterns being exceptions. Stainless will be the best choice for most people – professional chefs and home cooks alike.

Return to the Table of Contents

Blade Construction and Finishes

While Eastern knives are forged using the same methods of hot forging, stamping, and stock removal techniques as their Western counterparts, manufacturers aren’t shy about using the processes that create laminate, clad, or composite blades.

Cladding

Many knives of a traditional Japanese style will have an exceptionally hard core of high-carbon steel that is then sheathed with over-layers of one or more steels.

The exterior layers will typically be of a more ductile material that protects the inner core, and the combination results in a final product that blends an extremely sharp edge with easy sharpening.

Laminated

This a forging process where a hard carbon steel is enveloped with two layers of stainless steel, which are then forged together under extreme pressure and high heat.

This Yoshihiro Super Blue Steel Clad Gyuto has a center of super hard carbon steel covered with two layers of softer stainless material. Available on Amazon.

Like cladding, the laminate of a stainless steel exterior reinforces the super-hard core. It also adds the properties of stain resistance, which reduces maintenance. The result is a very sharp cutting edge that will hold its edge longer, and is much easier to re-sharpen.

Composites

A composite blade is constructed of two different steel alloys, which are then joined by brazing.

Brazing is a four-step process that permanently bonds the tool steel with a carbide such as tungsten, and a brazing agent like copper. This allows the manufacturer to use a premium grade, high-carbon steel for the core for a superb cutting edge, without the expense of using it for the entire blade.

It also results in a unique, decorative wavy line of copper behind the edge, which is revealed in the grinding process.

Design

Along with the greater diversity of design functions, some of the knives described above also offer stunning aesthetic styling.

Processes such as hand hammering, the flowing grain of Damascus cladding, graffiti-etching to designate the maker, and the wave-like pattern of composite blade technology turn these common kitchen tools into works of art.

And the distinctive beauty of these features elevate them into a world-class league – often with world-class prices to match.

Damascus

You’ll often see Japanese knives crafted with Damascus steel, which features the beautiful wavy patterns that are reminiscent of watered silk.

Traditional Damascus is a crucible steel, composed of at least two different high carbon steels with similar hardening and tempering properties that are forged together.

When heated, the intermixed metals absorb carbon from the hot charcoal and produce a visible crystalline structure. As the billet is forged and shaped, the crystals form the familiar wavy or water-like patterns.

This beautiful set from Yoshihiro features 16 layers of Damascus cladding. Available on Amazon.

Highly labor intensive, classic Damascus steel requires constant temperatures and a great deal of skill to create a product that has plastic properties while it is simultaneously very hard.

Today, most knives labeled Damascus are produced by wrapping an etched cladding around a core of hard steel, leaving the cutting edge exposed. Much quicker to manufacture, the water marks are created by the etching process.

Care needs to be taken when sharpening a Damascus blade, as the cladding can be scratched easily. To avoid damage to the wave pattern, a common practice is to apply thick layers of tape over the clad area while sharpening.

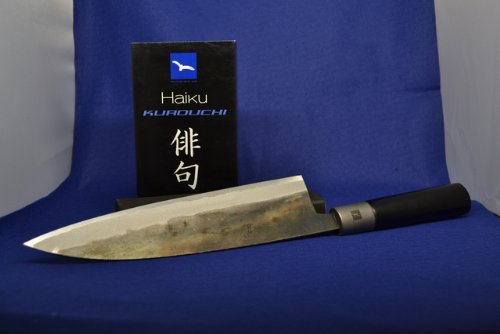

Kurouchi

A kurouchi finish has an old world look that gives a knife great character.

Also known as a blacksmith’s finish, kurouchi is a residue left over from the forge. It has a somewhat scaly appearance that reduces reactivity on high carbon blades.

This Haiku Kurouchi Gyuto is a beautiful example of this rustic style. Available on Amazon

Each blade will vary in appearance, and leaving this finish in place also reduces production costs. This is because the final polishing step is eliminated, which makes these knives a more affordable option.

Some believe the rough, unpolished finish also provides greater food release. Prized by many knife connoisseurs, the kurouchi finish gives a rustic aesthetic that adds charm to any knife collection.

Hammered

A hammered finish, or tsuchime in Japanese, adds a lovely handcrafted aesthetic to a knife blade.

But it also has a functional purpose. Each small divot created by hand hammering creates a little pocket of air, which reduces drag and provides a quick release from food on the blade.

This VG10 stainless Gyuto by Yoshirhiro features a hammered finish on the top of the blade, as well as Damascus cladding on the bottom portion. Available on Amazon.

The tsuchime effect is created with a smooth-faced hammer, like the round end of a ball peen, after which it’s given a final polish to remove any high points.

Return to the Table of Contents

Handle Shapes – Yo vs. Wa

Wa handles are the traditional Japanese version, and are most often made of Japanese magnolia – a wood that doesn’t require a lot of maintenance and doesn’t become slippery when wet.

The profile of these handles can vary, but they’re basically a wooden dowel attached to the blade, with common shapes being an oval, octagon, or D-shape.

The diameter is generally about 0.75 to 1 inch and approximately 5 to 6 inches in length, depending on the size of the blade.

Typically, a wa handle will taper slightly from butt end to blade heel, without a bolster – the tang is not full length, and it is burn set directly into the handle either with or without a ferrule.

Yo handles are an adaptation of Western handles and they have the same characteristics, shaped to form an ergonomic grip and affixed to the tang either with or without a bolster.

Yo handles usually feature a full tang, with the handle attached with stainless steel rivets.

Right vs. Left Handed (Grind and Handles)

For left-handed users, care needs to be taken in both handle selection and the type of bevel.

Wa handles of an oval or octagon shape are suitable for either right of left-handed use, while D handles are designed for righties – although many lefties find the D shape to be perfectly acceptable and comfortable to use.

Most yo or Western handles are suitable for both left and right hands, unless there’s a specific design element favoring the right hand.

Single beveled blades are ground for right-handed users, and adapting to left-handed use isn’t as comfortable or successful as it is with handles.

For a leftie to use a knife such as a yanagiba, the cutting edge is opposite to the dominant hand, making it difficult to see the cut properly. And the guiding hand is exposed to the very sharp edge on the right side, which can result in a nasty cut.

Single-beveled blades can be custom made by a blacksmith for left-handed use, and many manufacturers will produce a left grind on request. But both options will cost extra.

Return to the Table of Contents

The Saya

Some Japanese kitchen knives come outfitted with a Saya or a wooden sheath for transportation.

Although not necessary for the home cook, a professional chef may find having one of these useful for going to and from work, even if it is just to keep these incredibly sharp cutting instruments from slicing a hole in his or her knife roll.

These are usually only available for those blades which have “wa” style traditional handles but you may occasionally find a Western style knife that has a saya available as on optional accessory or included with the purchase.

Not all are built equally. Some are custom built for that exact pattern. These are pinless and use friction to stay in place, while others require friction-fit wooden pins to remain attached.

It’s possible to purchase generic models, but fitting them to the exact profile of your blade may be frustrating.

Return to the Table of Contents

Sharpening

Because of the hardness of the steel used, Japanese knives require a sharpening regime somewhat different from their Western counterparts.

To prevent chipping or removing too much material, care needs be taken when sharpening. Using a Japanese made waterstone is the best method.

King Two Sided Sharpening Stone with Base – #1000 & #6000

To get started, you can get by with a basic set of King waterstones in 1000 and 6000 grits.

As time goes by, you can add to your sharpening arsenal with finer and rough grits to either put more of a polish on the blade, or to repair chips and broken tips.

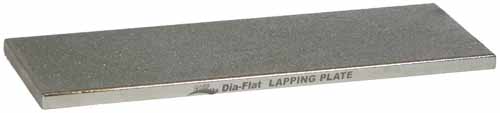

A stone flattening device is also useful to have, or else your waterstones will start to become concave as more material is removed from the center.

The creme de la creme of stone flattening aids is the DMT DIA-FLAT shown above, but serviceable substitutions can be made with a flat granite tile and wet/dry sandpaper.

A leather strop is also useful for removing any remaining burs.

It should be noted that Japanese knives are sharpened to more acute angles than their Western counterparts, typically 15 degrees though some will even go as low as 10 or 12.

Since the steel is harder than that found in Western knives, it can hold these more acute angle without rolling.

Return to the Table of Contents

The Final Slice

Thinner, lighter, and sharper, Japanese knives require a better technique on the part of the user, but they also provide unparalleled rewards for the knife enthusiast.

While it’s easy to get swept away by the striking appearance of these blades, it’s important to remember that their primary purpose is still that of a cutting tool.

Look for function and ergonomics as your main considerations. Sharpness, holding a good edge, ease of re-sharpening, balance, and comfort are the important factors – appearance should be a secondary consideration.

So what do you think? Would you consider purchasing one of these top-performing beauties if you thought it would improve your cooking skills and enjoyment in the kitchen, or are you happy with the status quo?

Let us know your opinions in the comments below, and don’t forget to check out the best knife storage solutions, in addition to the rest of our knife guides and reviews.

Don’t forget to Pin It!

Originally posted December 23, 2016. Revised and updated February 28, 2017.

Credited photos by Mike Quinn © Ask the Experts, LLC. ALL RIGHTS RESERVED. See our TOS for more details. Uncredited photos courtesy of MAC, Torijo, Wusthof, Kershaw, and Victorinox.

About Lorna Kring

Recently retired as a costume specialist in the TV and film industry, Lorna now enjoys blogging on contemporary lifestyle themes. A bit daft about the garden, she’s particularly obsessed with organic tomatoes and herbs, and delights in breaking bread with family and friends.

This is an excellent review. Simple, direct and great information. I particularly like that you emphasize the handle. This is a much overlooked area of choosing the right knife. If it doesn’t feel right and comfortable in your hand, you just won’t use it.

Also, I am unfamiliar with the zMisono brand. I will need to check this out: very attractive.

And finally, I will root around your site a bit more to learn about your garden – specifically how you feel about heirloom tomato plants.

Thanks for the great info.

Glad you enjoyed the article Rodman, and I agree completely… a well-built, comfortable handle is a must!

And if you’re interested in gardening, check out our sister site https://gardenerspath.com/ for some great articles. Thanks for your thoughts!

What is the name of the knife with unique hammering design. It is beautiful. Great article by the way.

Are you referring to the Enso HD 6-Piece Steak Knife Set Ryan? They are gorgeous… Glad you enjoyed the article!

Stellar article. Lots of information presented clearly and succinctly.

Thanks Jeff, appreciate your thoughts!

Thank you very much for this excellent, comprehensive, detailed and informative article. You’ve answered every question I had concerning Japanese knives. Now to go buy myself a set!

Amazing post! I wan to buy a knife to complement my chef knife and I want it to be Japanese this time. Something smaller preferably for more general cutting but without have to bring a huge one—small kitchen!

Go for a 5″ santoku knife. I prefer it to chef’s knife, handle’s way better imo.

Excellent post, detailed and informative, all my questions answered about Japanese blades and handles.

Nice and pretty informative helpful, post. thanks.

I am still a white steel fan and an avid home gourmet chef all my life. Stainless is good too, but the speed with which they dull is very unfriendly to deal with once a person gets used to having sharp knives. The rusting is not a big factor as everyone makes it sound. Wash it, wipe it, dry it, done. After a year or so it stops anyways.

Sharpening is the greater complexity for everyone to deal with, and most home cooks eventually get frustrated and just go buy a new (stainless) knife.

Its a never ending dichotomy between simplicity and utility values.