We occasionally link to goods offered by vendors to help the reader find relevant products. Some of these may be affiliate based, meaning we earn small commissions (at no additional cost to you) if items are purchased. Here is more about what we do.

I’m not going to lie… wood cutting boards are my absolute favorite variety among the many different materials that are available.

Chopping into a nice, thick end-grain board with a high quality kitchen knife gives off a baritone ring like Dean Martin in a rendition of “Volare.” Perfection made into sound. The best wooden chopping boards are produced using at least three different construction methods, which we will outline here. The qualities of the available types should influence your purchase, as well as intended use use, and of course your budget.

Types of Wooden Cutting Boards

Flat Panel

These cutting surfaces are typically constructed simply by gluing boards together edge to edge, just like a wooden table top. You are able to identify these as each individual wood piece will be wider across the top of the surface of the butcher block.

If you looked at the board from the end, you will be able to see an arched or “cathedral” appearance on each board (the end grain). A face grain board is the cheapest to make and buy, but tends to have a very high degree of warping and splitting over time.

A face grain surface.

This warping effect is caused by the movement of wood as it releases and gains moisture. All wood has some movement due to its ability to soak up airborne water or shed into a drier atmosphere – this typically occurs in different rates in various portions of the board(s) due to the differing density of cellulose fibers that make up the composition of a tree.

If you ever moved from an extremely damp climate to an extremely dry climate, you can see this effect firsthand. And it is sometimes noticeable in various wooden furniture or objects in different seasons of the year.

Since a cutting board is in frequent contact with water and other liquids, it is more prone to warping than many other wooden items that are made using similar construction methods (i.e. most table tops).

There are, however, construction techniques that can minimize warping and cracking. The two methods commonly used today include gluing the panel up in an edge grain configuration or gluing the boards up with an end grain construction technique.

Edge Grain

Moving up in quality and price, you’ll find edge grain boards. Similar to the construction of bowling lane flooring, this type has a series of boards that are glued up face to face, leaving thin, narrow bands running across the surface.

Normally thicker than the face grain varieties, these are much less prone to warping than their face-grained cousins, and are where I would want to start my search if I were on a budget. These are probably the sweet spot in the wooden cutting board category for price versus performance.

An older edge-grain cutting board showing signs of use and scratch marks.

Edge grain construction can make for very nice products, and other than scratch marks being more visible on these than on the end grain varieties, they make excellent cutting boards.

One additional benefit is that they do not have to be as thick as the end grain products to minimize chances of cracking or splitting.

This means that they may be made lighter, and thus they are easier to heft into a sink if you wish to do so. Also, most “butcher block” countertops are manufactured with this method (with some notable exceptions).

One of the better made wooden cutting boards out in the market for this type of block is from the John Boos Company.

These are made in the USA from American-grown maple and are very nice. They come in a variety of sizes and thicknesses to fit your countertops, so you can be assured that you can fit at least part of the board into your sink for easy cleaning. These are available via Amazon.

John Boos RA03 24 x 18 x 2 1/4-Inch Reversible Maple Cutting Board available at Amazon

Rubber cutting boards such as those from the Sani-Tuff brand are another option in this price range, and they may be a better fit for someone looking for a board that that they can run through the dishwasher.

End Grain

The crème de la crème of cutting boards are the end grain variety, and these have the traditional “butcher block” appearance. The wood that comprises these examples is joined together so the end grain faces the work surface. The end grain can be thought of as the very end of a typical board, as is shown below.

End Grain vs. Edge Grain vs. Face Grain

The benefits of this type of arrangement are numerous. You can think of the end grain as similar to the bristles of a broom if you are looking directly at the bottom:

Slice down with a thin, solid object, such as a top-of-the line chef’s knife, and the bristles merely move aside and let the object pass in between. Remove the object and the bristles return to their original position. The end grain of a piece of wood functions remarkably similarly, and thus can “self-heal.”

Moreover, end grain construction does away with any worries you may have about splinters. Although uncommon with a properly constructed face or edge grain cutting board, it is possible to have a piece split off in these products. This is impossible with a butcher block type of board, as the direction of the wood fibers faces a completely different direction and thus is not prone to splintering.

A closeup of end grain with an oiled and finished surface

Furthermore, end grained constructed butcher blocks are normally thicker than any other kind of unit – meaning there is almost no chance of warping (although on a very rare occasion they can develop cracks), and creating a very stable platform with no chance of flexing.

The only downside to this design is that they are typically much more expensive than other models made from wood, and are often four to fifteen times as expensive as a face grain unit. This is due to the amount of labor required to construct these products. Since they contain many individual pieces of wood, they are generally assembled by hand either in a factory environment or as a “one off” example made by a skilled craftsman.

But, you get what you pay for. Most of this type are heirloom quality, and may stay in your family for multiple generations – does it get any greener than that?

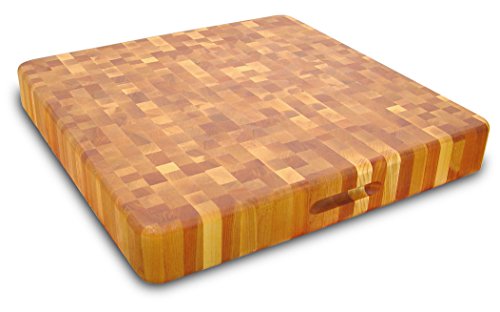

Catskill Craftsmen Super Slab with Finger Grooves

Once such example of end grain construction is the Catskill Craftsmen Super Slab pictured above – a very nicely made four-inch maple end grain block that’s available for a relatively low price and with very positive reviews at Amazon. Folks, I’m really impressed with this block for the asking price.

Type of Wood

The type of wood used to construct your butcher block can also have an impact on its appearance, cleanliness, and ability to help keep your kitchen knives in tip-top shape.

Cutting boards should be made from a closed grain hardwood. One that is not too hard and that comes from a tree which produces edible nuts, fruits, or syrup should be used– this helps to identify those woods that are safe for contact with your food, and do not contain toxins that can leach out.

The most common tree variety that has been in use for this purpose for the past several hundred years is hard maple. Other common and recommended woods include cherry and walnut. These are all closed grain hardwoods that aren’t too hard on your knives’ edges.

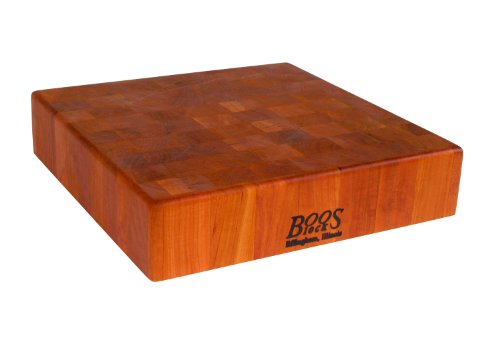

John Boos 14 x 14 x 3-Inch End Grain Chopping Block in Cherry available at Amazon

Open-grain woods such as oak and ash should be avoided, as they have many pores that can harbor bits and pieces of food, and that provide a good habitat for bacteria to flourish.

Other species that you should avoid are most tropical varieties – these often contain toxins that they produce in order to keep the plethora of insect and microbial life found in the warmer regions from eating their way into the tree’s flesh.

Another wood that is often used but should be avoided is teak. Although highly resistant to water and decay, teak is an extremely hard wood that also contains a lot of silica that can quickly wear down your expensive knives.

Woodworkers that handle a lot of teak generally go through a bunch of carbide blades trying to shape this material – you may consider what that does to the edge of your kitchen knives before adding a cutting board made of this material to your shopping list.

Fee, Fi, Fo, Feet

Some of the better cutting boards are available with feet, and these have their pluses and minuses depending on the thickness and weight of the board. With heavier examples that stay stationary on your countertops (i.e. you generally clean them in place), this allows you to get under them to wipe down the counter.

However, I don’t really recommend them for lighter and thinner products, as raising them up reduces friction between the board and your work surface, and could possibly allow them to slide around. Moreover, they can be difficult to deal with when you are buying a thinner unit that you would like to lift and carry to the sink.

John Boos Cutting Board with Feet, 12 x 12 x 1.5-Inch, Walnut available at Amazon

She’s Got Legs

Some of the most expensive and very best cutting boards have their own set of legs, and these are what most folks think of when they picture an old fashioned “chopping block.” These usually feature 10-16 inches of solid maple or cherry end grain, and weigh about the same amount as a small car. Needless to say, you aren’t going to lug one over to your sink for cleaning.

It really takes a special kitchen to house one of these battleships, and if you have the room, then by all means treat yourself. I actually have the same John Boos block pictured below that I scored off of Craigslist for $75. It now resides in our garage for mass home canning, BBQ, and fish fry type activities because I couldn’t make it work in our kitchen.

However, these behemoths are very nice, and if you can fit one in your space, then they are worth considering.

John Boos 18×18-Inch Natural Maple End Grain Butcher Block Table, available at Amazon

Cleaning for me normally involves a bout with the water hose (if it were in the kitchen I’d skip this step) and a spray of diluted vinegar or a diluted bleach mixture. Occasionally, I throw some food grade mineral oil on it and let it have a good soaking. And then I’ll finish up with a little beeswax. Both are nontoxic wood finishes.

If I were to buy one new, I’d pick one with a different leg configuration (Boos offers a bunch of different versions) as mine has a touch of 1970s country – I don’t mind the 1970s (especially the music) and I don’t mind country, but when you put the two together in terms of décor, I’m not a huge fan.

My last piece of advice – If you need just one fantastic cutting board that you can use for the rest of your life and even pass down to the grandkids, I would suggest a three- or four-inch end grain product in whichever dimensions you require. If you look after it properly, it should last multiple generations.

Note: If you are considering an end grain cutting board, I really wouldn’t go with a 2-inch or thinner version, as there have been reports of them splitting if they were not cured properly (i.e. allowed to dry out after harvesting), or were moved from an extremely wet climate to an extremely dry one. It seems that the extra inch on a three-inch version makes all the difference in terms of strength. Please also be aware that there is an inherent risk of cracking and splitting with all solid wood products – this is an organic material with cell walls that was once a living organism, and is not inherently stable.

About Lynne Jaques

Lynne is a stay-at-home mother of two boys. As a former US military officer and the spouse of an active duty US military member, Lynne enjoys traveling the world (although not the moving part!) and finding new cuisine and methods of preparing food. She also has the habit of using parenthesis way too much!

I had no idea that there were so many different chopping board constructions. Next time I am in the market for one, I will pay more attention to the construction and the type of wood it is made of. What is your opinion on bamboo cutting boards and chopping blocks?

Nids,

I’m not a huge fan of bamboo. They are very hard due all of the glue that is required to bond the thin strips of material together. Moreover, they contain large amounts of Silica that acts as an abrasive to the edges of your knife. You can read my opinion of them here:

http://en02-phx.stablehost.com/~lynnesca/gadgets/knives-cutting-boards-kitchen-shearschoosing-knife-friendly-hygienic-cutting-board/

That being said, for the average person that doesn’t maintain their knives and keep them sharp, bamboo will serve quite well.

Hope that helps

Lynne

I’ve got one of those huge free standing boos blocks and another custom made smaller unit from the Boardsmith and absolutely love both of them and wouldn’t want to give up either one. If you purchase a good one, your great grand children will appreciate it as they will last that long!

We’ve got some commercial boos products at work (Sushi bar) and they are absolutely killers. We’ve actually got a who wall line with 5′ table with one of their blocks as the surface. It’s one of the best places prep all of the ingredients in the place! I want one, a smaller version obviously, for my home ASAP.

“gives a baritone ring like Dean Martin in a rendition of “Volaire.”” Hee, hee, He WAS quite the crooner wasn’t he? Such a neat comparison.

So a ‘flat panel’ is the same as a ‘face’ panel? When I look at the picture of the large wooden planks that show the difference between, face, edge and end pieces, it seems like someone could just lay a plank out on a workhorse and cut off a square section (if you can picture what I am saying) and just use that small hunk with the ‘face’ as the cutting surface (after sanding and preparing the surface of course) Taking little pieces of ends and edges or strips of faces and gluing them together seems counter intuitive. But I’m not a wood handler so I’m sure there must be a reason for doing it the way they do.

Ria,

Yes a flat and face panel would be the same.

In terms of the differences between face grain and end grain on the effects on the edges of you kitchen knives, I’ll give you a comparison.

Say you have a bunch of straws. You lay the bundle out so that all of the straws are in line and parallel with each other. This is the equivalent of face grain. Now try passing your hand through the straws in a perpendicular manner – you can’t right? Why? They are solid matter.

Now grab this same bundle and turn it toward you so that you can observe all of the straw ends on one side. Now form your hand into a sort of karate chop. Try sliding your hand through the end of the bundle. Most of the straws shift position and allow your hand to pass through. Correct? This is end grain.

Its all about how the wood naturally grows and how the structure is naturally formed.

I hope this makes sense.

Cheers

Lynne

Ria,

I’ve attached a photo so you can better see my wood grain and drinking straw comparison.

Cheers

Lynne

Never knew there were so many variants. I’ll probably pick myself up a new one soon. Do you know of a store where I could check out some of these products? I’d like to be able to see the build quality and just how much I like it in person before having to buy the product on Amazon.

I so want a wooden chopping board! We are stuck with flimsy plastic ones at the minute as we have just gotten our first house! As soon as I get paid though I will be purchasing a wooden one! They last a long time and you don’t have to worry about wear! As one of the comments above said ‘even your grand children will be able to appreciate it’.

I’ve read all of your posts on cutting boards, ad I’ve decided it is time to replace my admittedly gross white plastic boards. I honestly had never noticed that wood boards had so many variations in grain. I had a few wood boards years ago, and they all ended up splitting. Which is how I ended up switching to plastic. Now I know why they split!

I’d *love* to buy a quality end grain piece, but cost is always a problem for me. I think I’ll just have to keep my eye out at yard sales and flea markets. I could get lucky! Although, I just did a quick browse at Etsy, and there are a lot of really nice end grain boards on offer fairly reasonably.

I appreciate all the research you do to give us good information about all these kitchen tools. Valuable information!

Okay, You may want to check out the options from Catskill. Made in the USA and reasonably priced (which is usually unheard of).

Wow. I always thought my choices were bamboo, plastic, or wood (in pretty colors and forms). LOL This is super informative and it’s something to study and consider when you’re going to buy one. I mean, the article has even made me want to go out and buy a wooden one.

This has been very educational. I knew the basics of do’s and don’ts, but the specifics always left my head in a whirlwind. This breaks it down easy enough for me to know what my next purchase will be!

Really great, informative article. I have a few cutting boards which I purchased based on aesthetics only. I really had no idea that the types of grain/wood affected quality! Now I know and can spend/save dollars when I wish. Thank you very much!

I love all the different types of cutting boards, but my favorite are the homemade ones that I can make. They are not very hard to make as long as you have the right tools and are pretty cheap. I usually will give them away as gifts during the holidays.

I have found that cheap wood is terrible for this purpose because the knives can cut slits and they get worn out faster. Now that I have been making them for some time I tend to buy better wood because I don’t mess up very often.

You should try making your own if you have the skills and equipment!

I didn’t realize the type of wood could affect my knives. I personally used molave and bamboo in the past. Molave is a hardwood with a very fine smooth texture. I never really considered they came in so many designs. This is an eye-opener for me.

I never knew there was so much theory behind wooden chopping blocks. In the past, I have bought cheap boards, only to find that they quickly warp and split. Now I know why this happens! I do think they look great in the kitchen and I’m now considering ditching my glass boards for something a little more traditional.

I have actually been in the process of slowly removing and replacing all my wood cutting boards with plastic ones because I was under the impression that wood ones held bacteria and they were breeding grounds for it. I only have one small and one large one left. That is really frustrating considering the cost and how many I already got rid of =( On the plus side, they kept the bonfires going a little longer. LoL!

Well, since I know this is not true now, I will just have to hang on to what I have left and start doing the replacement process back to wood again, and now that I know the differences between design and material, I can be confident that I am replacing them with good quality boards. Thank you for the information I need to make good decisions!

Wow this is a brilliant article. I had no idea how many different types of chopping boards their are. This is great information, I like ones that are easy to wash, because the spread of germs around the kitchen is one of the major causes of food poisoning.

Donna, I’d check out the sani-tuff line. 100% rubber and better for you knives and it’s dishwasher safe.

https://foodal.com/kitchen/knives-cutting-boards-kitchen-shears/cutting-boards/sani-tuff-rubber-cutting-boards-top-choice-home-chef/

Wow. I can’t believe that chopping boards have different properties depending on the grain of the wood. I found this article very enlightening.

A tip I had, because in our island we just chop off a portion of a tree trunk ( a round one, like an ‘o’) and use it, is to pick wood which has a lot of sap. They say that it sort of seals itself up and makes it easier to clean later on. Maybe a discussion on the kind of wood for your chopping board is also in order. =)

Jdzla, that one is easy to answer. In the USA, hard maple is the best followed closely by cherry. Both of these woods are closed grain, hard but not too hard, and have low silica content. Walnut is not too bad but the pores are a little bigger. Oak is out of the question – very large pores. Most soft woods are well…too soft.

Wondering if you have an opinion on or experience with “hard birch” wood for cutting boards; I have seen birch advertised as a good cutting board material in two separate places, but both were trying to sell their boards to me. Thank you!

Birch is a hard wood with a tight grain, so yes, it is a good material to use for making cuttings boards. Be sure to avoid putting it in the dishwasher, or submerging it in water in the sink.

Excellent overview. I had no idea that there were so many types to choose from. I really like to have one large cutting board to do the majority of my work and then several smaller, dishwasher safe varieties to do smaller projects or anything that may contaminate whatever I’m working on with the larger board. I think that end grain may be the perfect larger board as I don’t move it much.

It’s a general consensus that woodblocks are more prone to harboring bacteria and germs compared to plastic ones because they seep into the grain of the wood if the block isn’t properly and regularly cleaned. With that said, as long as you clean your woodblocks thoroughly and regularly, you shouldn’t have any problems. Always make sure that they’re in good condition and use a different block when cutting poultry or any meats with skin still on them because of the increased risk of salmonella!

Tommy, where did you read about this “general consensus?” Every study that I’ve seen (including the one linked in the article) has found that wood harbors the least amount of bacteria in comparison to multiple pastic products unless the plastic is brand new and unscratched.

That’s pretty interesting concerning wood harboring less bacteria. I was also under the impression that the depth of wood cutting boards & the way wood can retain water when not properly dried would be the perfect atmosphere for germs. However, I should admit I never really did any research on the matter. Thanks for the informative argument.

My kitchen counter tops are made of walnut and are for aesthetics rather than cutting on. You might say I have a thing for wood and yet your article shows there is so much to learn. I am embarrassed to not know about using nut, syrup, or fruit wood when it comes to combining wood with food preparation.

I try to keep a good amount of cutting boards around because cross contamination does worry me. The sound of knives on glass bothers me but I do prefer glass ones for meat prep.

I never believed a wood chopping block would make a big difference in the kitchen until I read this article. I’m pretty ashamed to admit that I basically had 0% knowledge about this item, even though I’ve been cooking for years. I should really do my homework on this!

I agree! I personally prefer slicing on wood compared to plastic cutting boards. It feels more natural and I am trying to stay away from plastic.

I recently purchased a bamboo block from Bed Bath and Beyond. I think it is a great alternative to using wooden varieties (as the nice ones can get very expensive).

I have used end grain boards for the past twenty years. I have three and use one for meat, one for fish and one for veg – the only exception being onions and garlic, for which I use a plastic board. I was told many-years ago not to ever scrub them with water but to scrape them. I must admit I do scrub them sometimes with water and vinegar and a wire brush, but mostly a scrape and then a wipe with vinegar and a damp cloth keeps them clean and fresh.

It’s good to see a review like this – I think they’re wonderful things.

This is such an interesting read. I received a beautiful wooden cutting board as a gift many years ago. It is absolutely beautiful and very heavy. I don’t remember what type of wood was used, I think either end or fine grained. However I was told I need to rub oil on it every once in a while to prevent it from drying out.

Is olive wood good for cutting boards?

I want to do all my counters in wood. I’m looking at walnut, because that is the tree I’m getting rid of. How long do I need to have it cured? I’m having the tree cut and cured by my tree cutter. They cure wood for furniture. Someone told me six months. Is this about right? It will be cut 2 1/2” thick. What are your thoughts?

Great article. Learned a lot. Thanks!

Very useful. I like your neutral and straightforward style. I’m getting the 20×20 Super Slab, thanks to you.

You should watch ” America’s Test Kitchen” video : The Best Heavy Duty Cutting Bords. They got very interesting results!

I have a few Byron Bay chopping boards made out of Camphor Laurel, These wooden chopping boards are really great, all one solid piece timber and have a natural anti bacterial property

Happy cooking

Mr Chef

Wow what a great site. I am hoping someone can answer a question for me. I was given to Twin J A Henckels cutting boards 14 in by 20 in. And one of them has little legs that flip down about an inch and a half only on one side? What are these legs used for and why would I want the cutting board up if that’s what they are for? I would appreciate anyone knowing with this beautiful board is to be used for with those 2 tiny legs.

Thank you

Nonnie Kaye

This is all terrible advice and you should investigate more. What a shambles…its no surprise that everyday people make bad choices. Shame on you.

Please enlighten us dearest Max. Please give us your sage advice and keen intellect so we may not go down the road of buying a bad wooden cutting board. Max, the wise, please lead us to the glory that is a proper chopping block.

You must be a troll? You have not provided a counter argument as to why the information presented here is bad? Please enlighten us? ????

May I suggest The K Board as an alternative? Far more practical, just as striking, and improves efficiency.

I believe they are only on Instagram right now?

@thekboard

Great article though!

Great article! Would like to add the combo of end grain and edge grain as I have a maple one in this configuration. It’s not as heavy as the end grain boards but stronger than most configurations….having grain in two directions…similar to plywood. It does show some markings on the edge grain but our Kyocera ceramic knives need little effort to cut our veggies which results in somewhat superficial cuts in the board.