We occasionally link to goods offered by vendors to help the reader find relevant products. Some of these may be affiliate based, meaning we earn small commissions (at no additional cost to you) if items are purchased. Here is more about what we do.

Despite all of our mothers’ repeated warnings, everyone here at Foodal loves playing with sharp objects.

We’ve been obsessed with cutting, slicing, dicing, and chopping our way through all of our many knife reviews.

So it should come as no surprise to any of you that we’re equally as excited to review yet another amazing cutlery piece…

Sorry, mom.

In addition to its premium line of direct-to-consumer basic cookware, the company Made In recently launched another kitchen essential that every pro chef and home cook needs to own:

The chef’s knife!

In this review, we’ll analyze the construction, materials, and design of this crucial cutlery piece from the company. We’ll also inform you on how to clean, care, and store it to maintain its high-quality performance.

What You Need to Know, Up Front

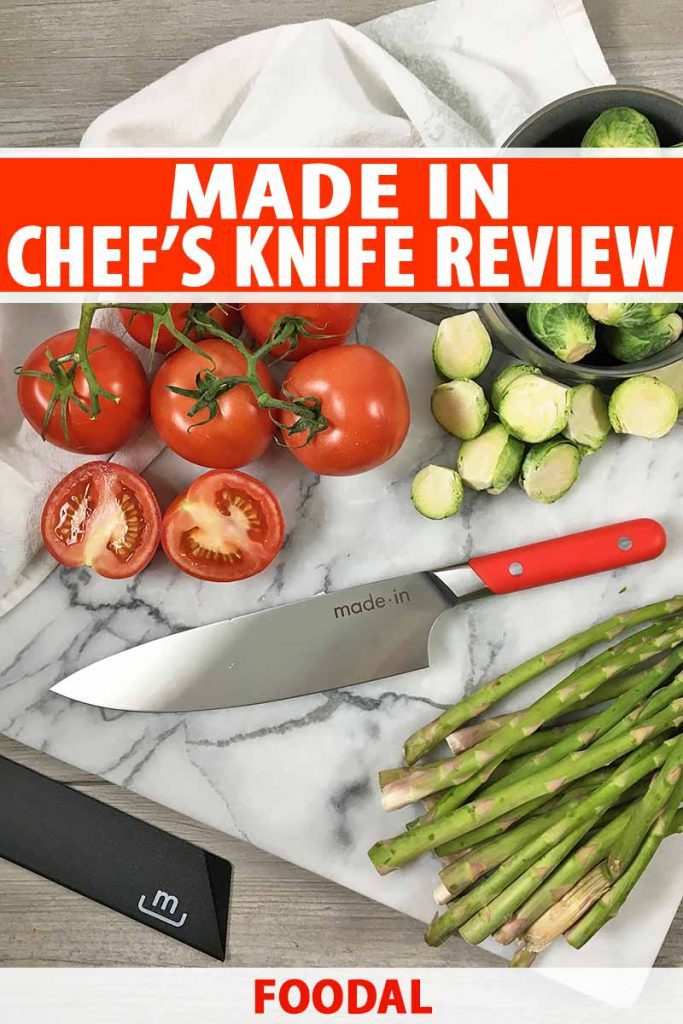

The Made In Chef’s Knife is a fully forged, nitrogen-treated blade made 100% in France. It is made from X50CrMoV15 premium metal, with a full tang and stainless steel rivets.

Chef’s Knife in pomme red, available from Made In

The blade is 8.5 inches long, and the entire length of the knife is 13 inches overall.

It weighs 0.5 pounds.

There are three different handle options to consider purchasing: pomme red, truffle black, or olive wood.

Bon Voyage, Made In!

From its start in 2017, Made In’s stark determination to become the leading kitchen brand has led the company from working with experienced manufacturers and materials in the United States, to traveling across the globe to France, in order to find the best resources possible for top-notch production.

For this cutlery piece, the company partnered with a knife maker in Thiers, France. This area is also known as the knife capital of the world, due to the city’s passionate history in the cutlery industry dating back over 700 years.

Made In chose this region for manufacturing due to a few core reasons, based on time-honored traditions and innovative techniques and designs.

Chef’s Knife in olive wood, available from Made In

So it’s not just because Thiers is a gorgeously breathtaking village in a mountainous region in one of the most romantic countries in the world… but I’d suspect that may have had some sort of influence on Made In too…

Family-Owned Business

Much like Made In, whose founders have a deep family history in the kitchen supply business, the Thiers knife maker they partnered with operates a family-owned business, respecting the longstanding traditions of forgery and metalwork across five generations.

The owners at Made In travelled to Thiers personally, to learn more about how both city and maker share in the innovations backing artisanal forgery and a passion for creating the best product:

Focusing on Fully Forged Metal

Thiers is one of few production regions in the world that still produces 100% fully forged knives from a single rod of metal, a rare practice today.

Made In’s knife is produced from a single rod of X50CrMoV15 stainless steel sourced from France, widely considered to be the best material.

The metal is heated and hammered into the blade, bolster, and handle – it runs the entire length of the blade through the handle, almost like a spine, giving it more balance and structural integrity.

There is no welding, stamping, or laser cutting, cheap and quick methods of manufacturing knives that create a blade that is less hard, less durable, and duller.

And partially forging knives, when the blade is welded to its bolster and handle, yields a tool with less balance and overall inferior quality compared to one that is fully forged.

Clearly, there are many advantages to using knives forged from just one piece of metal! The blade is stronger, sharper, and very durable. It won’t break down quickly, and will keep its sharp edge for a longer period of time throughout multiple uses.

Learning More about Nitrogen Treatment

Another unique feature that sets Made In apart from many other brands, these knives are also treated with nitrogen for long-lasting sharpness, strength, and corrosion resistance.

Many other companies add additional carbon to their knives for the purpose of yielding a harder blade. While adding more carbon strengthens the blade, there are some serious disadvantages to this decision – the blade is more difficult to care for, since it becomes more susceptible to rust, discoloration, and chipping.

Using a nitrogen-hardening treatment, rather than using additional carbon, offers the best of both worlds – it is both fortified and easy to maintain.

Here’s the basic process: before the rod is forged, the raw metal is first immersed in liquid nitrogen at a chilly -58°F.

Chemical compounds are actually transformed during this stage of production (from austenite to martensite), with the final result being a product that is stronger, sharper, and more resistant to corrosion… and a product that you don’t have to worry about polishing and sharpening after every use! Yay!

A Perfect Rockwell Hardness Score

To provide an accurate measurement of hardness, knife producers undergo the Rockwell Hardness test, which measures the hardness of steel with a numerical score.

Chef’s Knife in black truffle, available from Made In

The hardness of the blade is an important quality of a premium blade – one that’s too hard is more prone to breaking and chipping, while one that is too soft is dull and needs more frequent maintenance to keep the edge sharp.

The combination of a fully forged and nitrogen-treated knife strikes the perfect balance between hardness and softness – it is strong enough to withstand heavy usage, without the risk of breaking.

This gives the tool a superior Rockwell Hardness Score of 58-60.

Care and Keeping

Made In has made it so easy for us to clean, maintain, and store this piece of cutlery!

The company (as well as everyone here at Foodal) does not recommend cleaning it in the dishwasher. To maintain the quality of the blade, it is always best to wash by hand with warm, soapy water. Dry immediately.

Each one comes with a custom sheath as part of your purchase for safe and easy storage – and it can easily fit in any kitchen drawer when not in use.

But who are we kidding… we’ll be cooking with this French beauty in the kitchen constantly!

Warranty and Return Policy

Chef knives can be returned for a full refund if they are returned within 30 days, unused, and in their original packaging.

You can take advantage of free shipping, returns, and exchanges if you are unsatisfied with the product for any reason.

For more thorough information on their policy, be sure to read the warranty section of their website.

Any other questions? Contact Made In’s helpful customer service team – all of the contact information you need is on the company website as well.

French, Forged, and Flawless

For a sleek and modern look, a design built on time-honored French traditions, and innovative production techniques, consider purchasing the Made In Chef’s Knife!

You’ll be able to slice through your kitchen prep work with ease, thanks to the fully forged, nitrogen-treated blade.

Don’t settle for anything less than what is absolutely necessary for flawless kitchen performance – having reviewed both Made In’s cookware line and now its French-made cutlery tool, I continue to be thoroughly impressed by the company’s passion for superior, high-quality products sold at an affordable price.

You have the cookware. Now get the knife!

Do you already own or have you used a fully forged cutlery tool before? What do you think of it, compared to other designs? And let us know in the comments below what you think of Made In’s ever-expanding line of premium cookware and tools. We can’t wait to try whatever’s next!

Next up, take a look at some of our other reviews of Made In products, starting with these:

Photo credit: Credited photos by Nikki Cervone, © Ask the Experts, LLC. ALL RIGHTS RESERVED. See our TOS for more details. Product photos via Made in. Sample products provided by the manufacturer for testing. Originally published on November 21, 2018. Last updated on October 20, 2021. With additional writing and editing by Allison Sidhu.

About Nikki Cervone

Nikki Cervone is an ACS Certified Cheese Professional and cheesemonger living in Pittsburgh. Nikki holds an AAS in baking/pastry from Westmoreland County Community College, a BA in Communications from Duquesne University, and an MLA in Gastronomy from Boston University. When she's not nibbling on her favorite cheeses or testing a batch of cupcakes, Nikki enjoys a healthy dose of yoga, wine, hiking, singing in the shower, and chocolate. Lots of chocolate.

After watching Forged in Fire, I am fascinated with forged knives. Thank you for the wonderful description!

Happy to hear of your interest in forged knives, Ellie! Let us know if you decide to buy and try any of the knives we recommend!

Thiers, France is ” the world capital of knife making”? Are you certain about that?

Thiers certainly has some good knife makers. So does Seki city in Japan (a lot more knife makers in Seki than in Thiers these days, actually). And so does Solingen, Germany (again, numbers in Solingen are looking a bit higher than Thiers). Toledo, Spain. Sheffield, UK. I could mention cities in Sweden, Switzerland and Czech Republic with good numbers as well. And closer to home, even your native Pittsburg PA has several. Don’t forget the people over by Franklinville NY either. The list goes on.

Not quite sure Thiers is the world capital? Maybe define your parameters???

I would guess that those knives might get a cryogenic liquid Nitrogen treatment AFTER forging- And probably after some post forge rough grinding to shape/size + a hardening heat treatment/quench cycle, not BEFORE forging. Because doing it before hand would be a waste of manufacturer’s time and liquid Nitrogen.

Also, liquid Nitrogen quenching is about -196 C or -320.4 F., RATHER chillier than -54 F, which is not even as cold as dry ice.

Maybe that was just a translation error, French is so confusing and French people just INSIST on using Centigrade/SI units/metric system, almost like the invented that stuff or something. Oh WAIT. They DID?!

58-60 isn’t terribly soft, it’s nearly as hard as a good Japanese knife, mine run 61 to 65 depending on maker & use. Somewhat harder than tradtitional, easy to sharpen German (and French) knives, commonly around 56-58.

Say, that knife STEEL was SOURCED in France. The factory is where, again? Thiers, in France?

Why does “Made in” say that they sell solely USA made products then? Just looked at their January 19th interview where the owners said that.

I am SO confused.

Thanks for your thoughtful comments and corrections, Robert! Though describing Thiers as the knife capital of the world is certainly a matter of opinion – one that the manufacturer embraces wholeheartedly – other items that you have brought to our attention were factual errors. We will publish an update to this article as soon as possible, after we have received some additional details regarding the manufacturing process from Made In.

Made In does currently sell a product line that is completely made in the USA, except for their chef’s knife.

It’s bizarre to me to suggest that X50CrMoV15 is “the best steel.”. It’s certainly a common German martensitic cutlery steel, characterized by very good stainless properties, at the cost of edge holding. It’s a good knife steel if you’re proficient at sharpening and plan to resharpen your knives frequently. But if not, it may leave something to be desired. That appears to be borne out in testing done by other companies. This knife wasn’t able to make it thru the full battery of tests and still cut a tomato at the end.

There are a lot of much newer steels that are far better. This one is normally considered to be mid to high end, and certainly not truly premium.

Another metallurgical point here is that powder metallurgical steels tend to be better than older cast type steels because the uniformity of composition results in more uniform carbide formation. The layman’s version is that the different elements cool at different rates so you can get carbides (think crystalline formations) that aren’t uniform sizes if the composition isn’t even and evenly distributed. As the blade wears, the carbides break out, and can leave uneven gaps. Forging can also lead to problems because the nature of the process leads to uneven heating. As a result, blades must be normalized (run through a series of heat cycles to alter the structure to be more consistent). I expect the manufacturers here do a fine job, and it’s notable that they appear to be running the hardness 58-60, when this steel normally should be hardened to 58 as per manufacturer specs. More hardness leads to a sharper edge that can last longer, but also to brittleness. There’s nothing in the composition of this steel that really lends itself to high hardness tempering, so it would come down to the quality of the heat treat, and even then, you can’t really expect miracles.

This article reads very much like a regurgitation of claims made by the manufacturer, many of which are factually dubious. Drop the hyperbole and superlatives. It’s not the best steel, nor is Thiers the knife capital of the world, etc. It’s a competent steel that’s likely well made for what it is, but the nature of the steel means it will almost certainly require frequent resharpening, which can be a deal breaker for the average home chef. I do think anyone that wants to cook seriously should learn to resharpen, but nonetheless there are better steels in droves.

I agree with much of what you said. I’ve been cooking professionally for many years, and love knives, and I actually love this steel for its ease of sharpening, and honing. As you stated, it requires more sharpening, but since in a commercial setting there isn’t a knife, no matter how hard, that doesn’t, I guess I’m just used to running a ceramic steel over my knives lightly almost daily. Carbon blades are my favorite to use, but they can be a hassle in a high paced kitchen, reserved for jobs where I’m not going to be interrupted, and can just have fun with my toys. For a home chef, I can see where you’re coming from, but learning to hone your own knives isn’t hard, but again, depends on each’s needs. I guess I’m not much of a judge given I’m willing to hone, and wipe my blade constantly, and do the extras required of carbon steel. To each their own I guess, but great input regardless.