Considering a home espresso machine for lattes, cappuccinos, and coffee drinks at home? Have you heard about the benefits of E61 Group Heads but are unsure of what this device actually is?

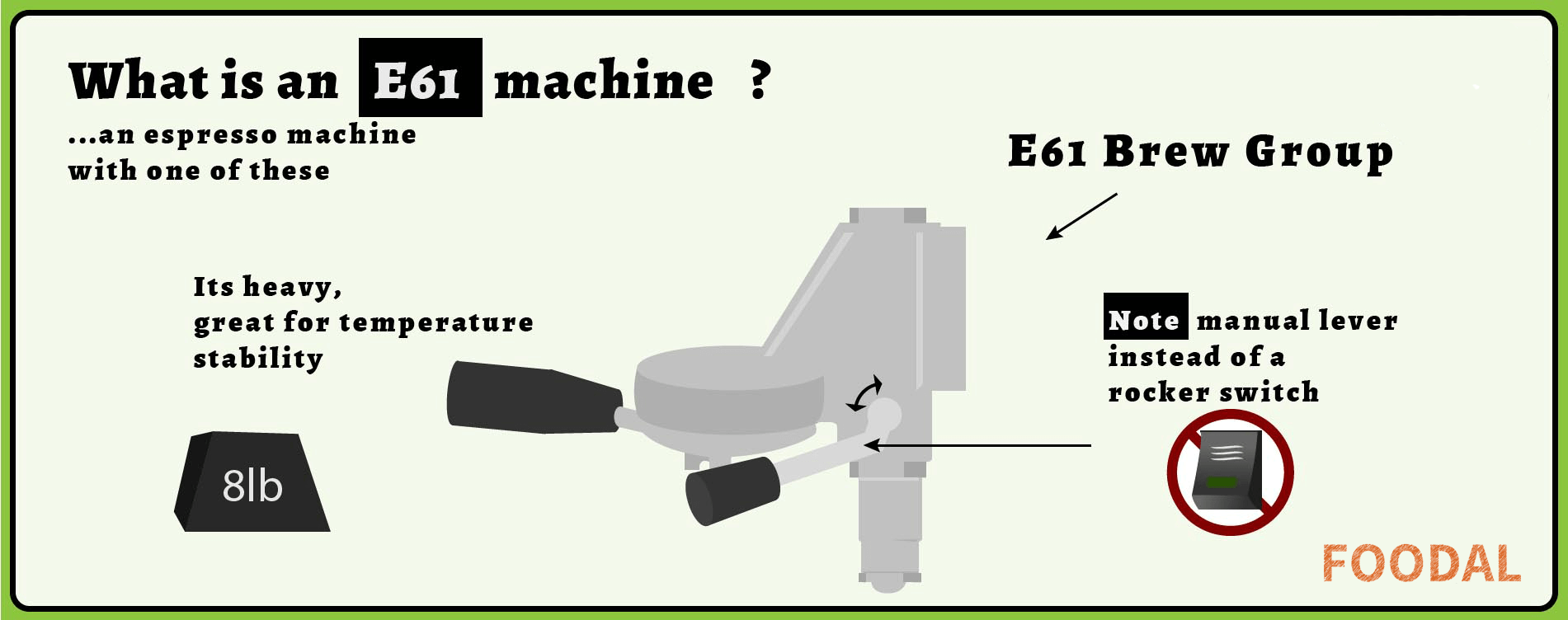

They are one of the premier control units that are very common in heat exhanger (HX) type espresso machines and are also featured in some dual boiler and even in a few single boiler/thermoblock systems.

Since these control units were originally developed for HX systems we will first discuss how these work in regards to these types of machines and then we will address the benefits of the E61 Group Head in regards to other types of espresso machines.

How Does an E61 Work?

Named for the year it was patented (1961, an Eclipse year) by Faema, the E61 heat exchanger is a semi-automatic system that manages the extraction process.

Since, the E61 is now off patent, there are several manufactures of this brew head to include Gruppo Cimbali (Cimbali Group) who now own the the Faema brand and VBM (Vibiemme) who used to own the Faema brand in there early 1970s.

This appliance allows for stable and controlled temperatures for brewing and frothing in a fairly quick manner from the same machine.

Because water for brewing the espresso should be kept at around 202 degrees F, and milk needs much higher temperatures for steaming purposes, this can cause difficulty.

Click Graphic for a Larger Size

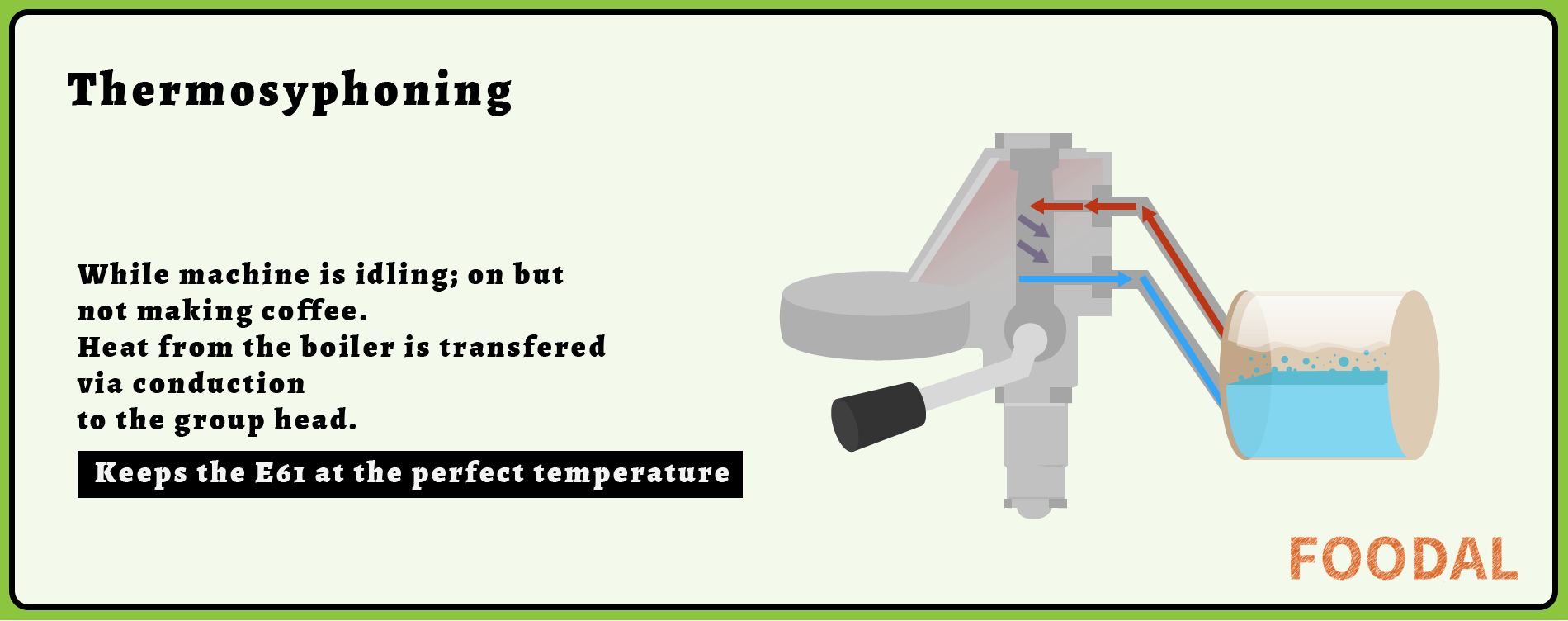

A heat exchanger unit seeks to solve this problem by keeping the boiler chamber only partially filled with water while a layer of steam is situated on top.

The patented E61 grouphead has a set of channels through which the water from the reservoir flows. There are input and output channels which allow the water to be kept at the constant temperature ideal for pulling espresso shots.

This keeps the shots consistent and offers a dependably uniform brew, without sacrificing the quality of the steamed milk.

Heat for Steaming

Because the chamber is under pressure, the temperature at which steam is created for frothing milk is around 257 degrees F.

The difficulty now is that once the ideal steam temperature is reached, the water temperature will eventually rise higher than an ideal brewing temp for the coffee.

Therefore, in order to pull a shot after milk has been frothed, the water must be brought down again to the proper temperature of just above 200 F.

Click Graphic for a Larger Size

To solve this issue, the E61 unit makes use of a flush of cooling water which will reduce the temperature of the water in the for ideal brewing.

This cooling process will be effective for many pulls in a row, but if the appliance sits for a few minutes then the cool down process will be necessary again.

Pulling Shots with the E61 HX

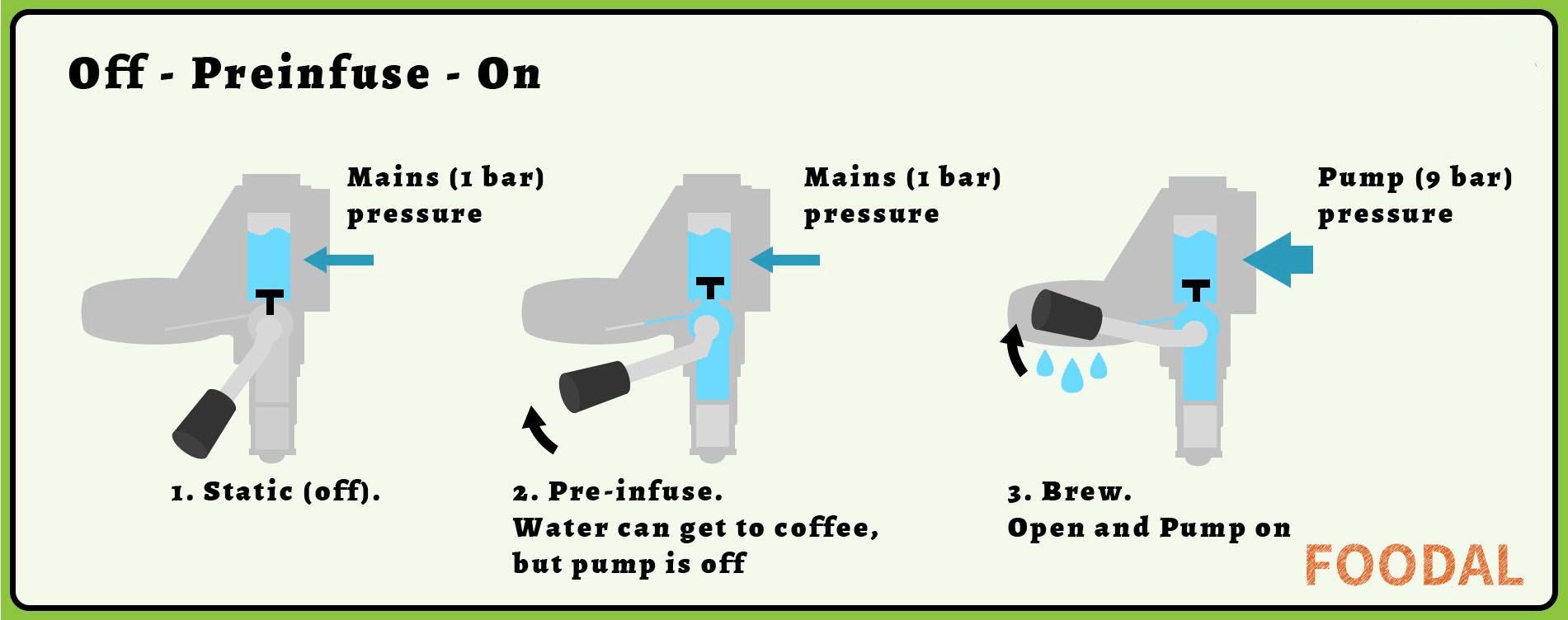

Other positive aspects of this appliance include a pre-infusion chamber which offers a high quality extraction.

This chamber give the opportunity for the coffee grinds to “bloom” by first allowing the water to seep through gently into the fine grounds which are tamped into the puck.

This process of blooming allows trapped gasses to be discharged prior to brewing, making room for the water to be amply exposed to the grounds and ultimately results in a richer, fuller flavor.

The pre-infusion chamber also creates a pressure which builds more slowly and avoids channeling within the puck.

Click Graphic for a Larger Size

Once the water begins to flow through into the cup, the lever is pressed down and the brew valve opens fully, allowing the perfectly heated water to be pumped through the puck for approximately 23 seconds.

Once the process is complete the lever is pushed down completely to close the valves and allow the portafilter to be removed.

At this point, your perfect cup of espresso topped of with light brown “crema” or foam, will be ready to add steamed milk if desired.

E61 Equipped HX Espresso Machine Models

Almost all Thermo-Syphon/HX based models made today feature the E61. Some of the more popular models include the Quick Mill Anita, Quick Mill Andreja Premium, Rocket Cellini Premium Plus, Rocket Giotti Evoluzione, and Faema Carisma.

Durability and Care of the E61

Because the heat exchanger machine is mostly manual and makes use of very few electrical parts, many consider it to be the most reliable system on the market.

A process called backflushing is necessary to perform every two to three weeks, depending on the amount of use.

Backflushing is the process of cleaning used to remove oil and other debris from the grouphead to make sure there are clear paths for the water to flow through.

As long as it is cared for properly and kept in good condition, you will likely find yourself enjoying consistent extractions for years to come.

Click here to read more about the proper cleaning of your espresso machine.

E61 and Double Boilers

Although saturated brew groups are now the rage within expensive commercial appliances, prior to their invention just about all espresso machines employed some kind of deviation of the traditional E61 brew group.

Since this is a tried and true design, many preimum double boiler models such as the Rocket R58, the Quick Mill Vetrano 2B, Quick Mill QM 67, and the Izzo Alex Duetto 3.0 have returned to their roots and are being released with the classic E61 model.

How does this improve the double boiler system? The aforementioned pre-infusion chamber is built into the group head requiring less additional parts that could break.

The saturated brew group design requires an additional pre-infusion unit to added into the design that increases complexity and takes up more room – sometimes this is built in as standard as in the case of the La Spaziale Vivaldi II or as an optional accessory as in the case of the La Spaziale Dream, Dream T, or Mini Vivaldi II.

Moreover, the 8lbs of weight still does its job of maintaining temperature stability at the brew head in dual boiler models. This applies to any machine that is E61 equipped.

In summary, an E61 Equipped Heat Exchanger (HX) or double boiler brings espresso brewing to a higher level than that of basic systems through the modulation of temperatures and through its built in pre-infusion capabilities.

It is a time tested device that has been around for decades and will continue to be around for decades more – making parts easy to find and matching up portafilters and other accessories an easy process.

Do you have more questions about espresso machines? If so, click on that handy dandy contact us tab floating on the left of the screen and shoot us an email and/or read more of our guides!

About Mike Quinn

Mike Quinn spent 20 years in the US Army and traveled extensively all over the world. As part of his military service, Mike sampled coffee and tea from all virtually every geographic region, from the beans from the plantation of an El Salvadorian Army Colonel to "Chi" in Iraq to Turkish Coffee in the Turkish Embassy in Kabul, Afghanistan. He spent nearly a decade in the Republic of Korea where he was exposed to all forms of traditional teas. Mike formerly owned and operated Cup And Brew, an online espresso and coffee equipment retail operation.

Hi Mike, I have a question regarding the whys of the possibility I have some backflush water “leaking” into the single hx machine’s boiler. I have a basic Expobar Office Control 2001 model which I found last year. It is like new. I do not drink milk drinks so, I use the boiler mainly for Americanos. I try to flush out all the water every couple of days in order to keep the water fresh. However, I have noticed a ‘tiny” amount of coffee grinds in the water (coming out of the water sprout). Since I only make two doubles a day, my cleaning routine is usually backflushing with a blind disc every week, and use the proper detergent every month. Since these valves should be one way and prevent any backflush from going into the boiler, what could be wrong?